Categories

New products

-

Lens Ring Joint Gasket

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Lens Ring Joint Gasket manufacturers and suppliers,our Lens Ring Joint Gasket factory can provide the products wiht high quality and favorable price.If you are looing for Lens Ring Joint Gasket,pls contact Kaxite.

-

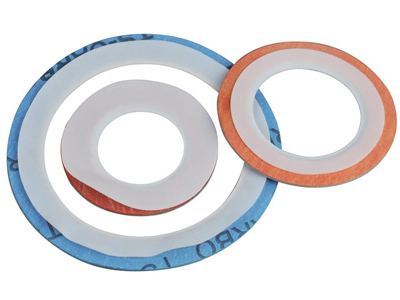

Double Jacket Gasket

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Double Jacket Gasket manufacturers and suppliers,our Double Jacket Gasket factory can provide the products wiht high quality and favorable price.If you are looing for Double Jacket Gasket,pls contact Kaxite.

-

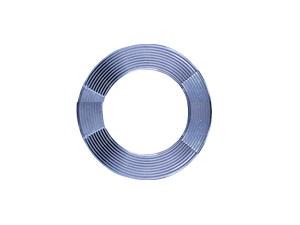

Corrugated Gaskets

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Corrugated Gaskets manufacturers and suppliers,our Corrugated Gaskets factory can provide the products wiht high quality and favorable price.If you are looing for Corrugated Gaskets,pls contact Kaxite.

-

PTFE Envelope Gasket

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading PTFE Envelope Gasket manufacturers and suppliers,our PTFE Envelope Gasket factory can provide the products wiht high quality and favorable price.If you are looing for PTFE Envelope Gasket,pls contact Kaxite.

-

Rubber Sheet

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Rubber Sheet manufacturers and suppliers,our Rubber Sheet factory can provide the products wiht high quality and favorable price.If you are looing for Rubber Sheet,pls contact Kaxite.

Double-jacketed gaskets

HIT:9 DATE:2015/3/25

Double-jacketed gaskets are another combination of filler material and metallic materials. In this application, a tube with ends that resemble a "C" is made of the metal with an additional piece made to fit inside of the "C" making the tube thickest at the meeting points. The filler is pumped between the shell and piece. When in use the compressed gasket has a larger amount of metal at the two tips where contact is made (due to the shell/piece interaction) and these two places bear the burden of sealing the process. Since all that is needed is a shell and piece, these gaskets can be made from almost any material that can be made into a sheet and a filler can then be inserted. This is an effective option for most applications.